Evaporator Coils, Condenser Coils, Water Coils, Steam Coils, Cooler Coils.

Cooler

Application

1. Storage of vegetables and fruits.

2. Commercial cold storage.

3. Commercial & industrial cold rooms and preparation rooms.

4. Freezing of bakery products, fish and meat.

Coil Properties

1. Unit Coolers are designed with optimum tube diameter in order to increase efficiency of unit coolers.

2. Optimized corrugated fin for high performance.

3. Fin spacing optional for specific application.

Casing

Casing with white coating for corrosion protection.

Fan

Upon customer request.

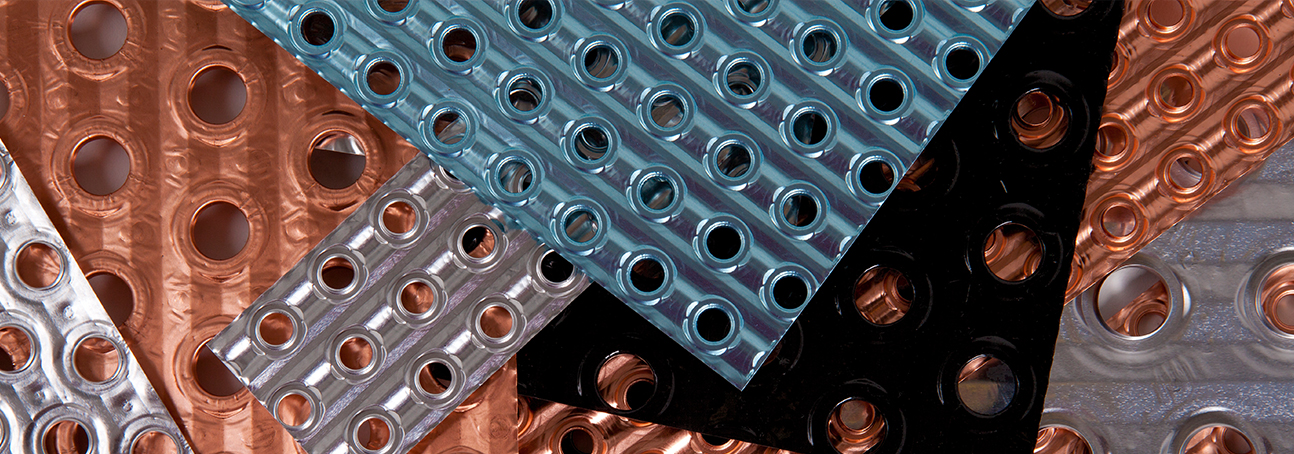

Materials

Fins

Regular Aluminum is the most common and cost effective fin material.

Copper has higher heat conductivity and mass, and is more costly than Aluminum.

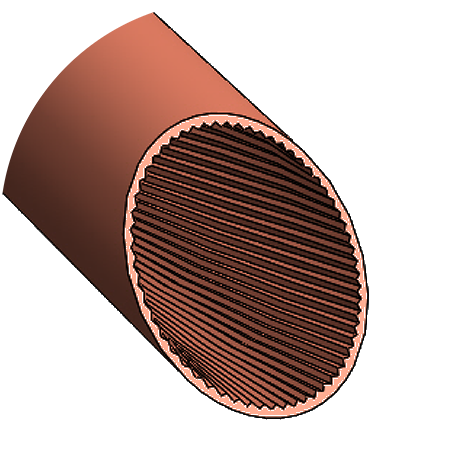

Rifled

Condensers and evaporators for increased capacities.

Smooth

Standard in all coils

Fins Shapes

Louvered

Louvered fins increase the heat-transfer capacity by creating air turbulence which reduces the boundary layer on the fin’s surface, but at a cost of increased air-pressure drop across the coil.

Sine Wave

Sine wave fins improve the heat transfer factor to a higher degree than corrugated fins. These have about the same resistance to air flow as the corrugated fins.

Corrugated

Corrugated fins improve the heat transfer factor to a lower degree than louvered fins. They also have a lower resistance to air flow.

Flat

Flat fins reduce ice accumulation on fins. They have the lowest resistance to air flow.

Products Gallery

Our mission

Our mission is to succeed in the market place through exceptional customer service, commitment to quality, competitive pricing, and on time shipments. Striving to be the reliable development partner with our customers.

Contact Info

Add: No 5 building, No 17, Second Alley, Qiaochang Road, Qiaotou Town, Dongguan City, Guangdong Province, China.

Tel: +86 400-678-8839

Mob: +86 138 2477 2972

Fax: +86 0769-23320649

Email: T[email protected]